Micropile specialized services

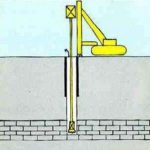

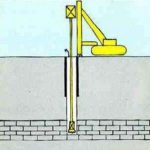

Micropile or micropile is often part of drilling and in-situ piles, of course, with a small diameter (mainly less than 300 mm), which is often reinforced with reinforcement.

Micropile or micropile is often part of drilling and in-situ piles, of course, with a small diameter (mainly less than 300 mm), which is often reinforced with reinforcement.

Employer: Engineer Amir Hosseini

Excavation depth: 18 meters

Excavated volume: 90,000 cubic meters

Type of guard structure: anchorage, monobar, soldier

Implementation period: 3 months

مشاهده ویدیوEmployer: Rekindej company

Excavation depth: 26 meters

Type of guard structure: self-drilling rod, multi-strand, pile with steel core, soldier pile, consolidation injection

Duration of implementation: 75 days

مشاهده ویدیوClient: Stara Omran Zameen Company

Excavation depth: 27 meters

Excavated volume: 46,000 cubic meters

Type of guard structure: strand and soldier, steel pile

Duration of implementation: 145 days

Contractor: Eastapi Exploration Company

مشاهده ویدیوThe vision of Ista-P Exploration Engineering Company, the provider of nailing and anchoring services, is planned based on the fulfillment of the following obligations, and the efforts of the managers of this company are to achieve these goals.

Complete design and implementation of projects in accordance with the regulations and compliance with the necessary standards

Fulfilling contractual obligations according to the specified schedule

Identifying quality improvement factors from design to project delivery and its continuous use

Updating the technical knowledge of engineers and employees and improving related skills and evaluating their performance

Nailing the wall wall or nailing is one of the other common methods in soil improvement and this method is implemented with the aim of reinforcing the existing soil mass. Or it is done vertically at the excavation site and then filled with cement slurry to prevent the corrosion of the rebars and better power transmission.

Because this method has become very popular over the past years and is considered a practical method. The use of nailing method in Iran has also developed significantly and is considered one of the most widely used methods, especially in urban constructions.

By creating a stable reinforced cross-section, the nailing method can protect the soil behind it and keep it in place. Nails usually work in tension, but in special conditions, attention is also paid to their bending and shearing performance.

Increasing the vertical force and consequently increasing the shear resistance of the sliding surface in friction soils

Reducing the thrust force of the sliding surface in frictional and sticky soils.

After the nailing rebars are installed on the surface of the gable wall or pit, a thin surface layer including shotcrete and light steel reinforcement in the form of rebar networks is implemented with the aim of preventing surface erosion of the soil and creating a more suitable surface for construction. The construction of these walls pursues a more important goal, which is to improve the performance of the consolidated soil system, especially in the parts close to the pit wall, and more suitable transfer of driving forces to the reinforcement marks.

۱. In the first stage of nailing, excavation should be done to a depth of 1 to 2 meters and to a sufficient width based on the strength and ability of the soil. It should be noted that the excavated width should be enough to install the equipment used for drilling without problems.

۲. In the next step, the necessary holes for installing the nails should be created. These nails include two models, solid (which is very popular) or hollow, and in order for the nails to have the necessary resistance and strength, a series of parts are used with the help of grout, which is placed in the distance between the two nails and the inner wall of the holes on the The nails have been placed. During the installation of the nails, they direct the injection tubes into the holes.

Note: Preventing rebars from rusting is a very important thing that should be considered at this stage, which is protected by using plastic corrugated covers. This reduces the rate of erosion of the used nails, and then the holes are filled with mortar. In the grouting stage, this should be done according to gravity pressure or with very little pressure.

Note: Geocomposite drainage strips should be used on the entire excavated surface and in the middle sections in the place where the nailing operation has been carried out. In addition, these strips need to extend to the end of the wall and by transferring water to the heel, finally transfer it out of the embankment through the drainage heel.

۳. In the third stage, the work of installing nails and grouting should be carried out, and in this stage, the soil should be braced before the next stages of digging the temporary shell. One of the most common types of these shells is a light reinforcement layer along with a 100 mm thick shotcrete layer. The reinforcement consists of a network of welded wires that runs approximately in the middle of the thickness of the shotcrete, the length of these welded wire networks should be enough to overlap at least one full spring of the network with the next welding wire network.

After that, the bearing plates are placed on the nails protruding from the holes and the nails are gently and with a little pressure connected to the freshly poured concrete layer. After that, the hexagonal nut and washers are firmly attached to the bearing plate on the nail heads.

Note: If necessary, tests are performed on the nails to measure displacement and prove the bearing capacity before the next excavation process. Before starting the next excavation process, the concrete sprayed area must be properly protected for at least 72 hours or to achieve a compressive strength of 3 days (for example, 10.5 MPa).

۴. It is necessary to level the excavated surface. For this, the first to fourth steps are done for the stability of the embankment. At the end of the excavation, the drainage strips are gathered in the heel of the embankment and make the drainage heel of the wall.

۵. At the end, a permanent shell layer is applied, which creates the final appearance. It is possible for the final shell to be made of reinforced in-situ concrete, reinforced shotcrete, or prefabricated concrete panels. Permanent coating reinforcements are the same as normal rebars or welded wire mesh.

It is as if the soil drift is restrained through the nailing system to the soil itself. Nailing was later used by German and French engineers to stabilize trenches, galleries, tunnels and bridge abutments.

After that, indigo was widely used in various construction projects, such as the stabilization of railway trenches and highways, the construction of excavated guard structures in urban areas for the construction of high-rise buildings that include several floors inside the ground, and the stabilization of land slopes against landslides. Potentially closed

. Nailing the walls means reinforcing the existing soil by installing steel rebars close to each other (Nail) on a sloping surface with a gentle slope of about 10 to 20 degrees below the horizon level or in the excavation site and with execution from top to bottom. In this implementation method, the nails (nails) are subjected to tensile stress during operation and provide the stability of the wall.

The strengths of the nailing method

Stabilization of slopes, gables, trenches

Improving the carrying capacity and reducing the amount of deformations

delivery of damage